What is Sulfuric Acid? A Comprehensive Guide to This Essential Chemical Compound

Sulfuric acid (H2SO4) is one of the most important chemical compounds in modern industry, playing a crucial role in manufacturing processes worldwide. Ever wondered what makes this colorless, odorless liquid so essential to our daily lives? From fertilizer production to petroleum refining, sulfuric acid’s versatility and unique properties make it indispensable in countless applications. In this comprehensive guide, we’ll explore: • The fundamental properties that make sulfuric acid unique • Its widespread industrial applications and significance • Essential safety considerations and handling procedures • The fascinating chemistry behind its reactions Whether you’re a chemistry student, industry professional, or simply curious about this powerful compound, join us as we delve into the world of sulfuric acid. Understanding this vital chemical is key to appreciating its impact on modern manufacturing and technology. Let’s uncover the science behind one of chemistry’s most important compounds.

Key Takeaways:

- – Sulfuric acid is a colorless, odorless inorganic acid that serves as both a powerful oxidizing agent and the world’s most widely used industrial chemical.

- – As a very strong acid and powerful dehydrating agent, it plays a crucial role in chemical synthesis, petroleum refining, and fertilizer production.

- – The compound is primarily manufactured through the Contact Process, which involves the chemical combination of sulfur dioxide with other elements under specific conditions.

- – Safety considerations are paramount when handling sulfuric acid due to its strong acidic nature and potential to cause severe chemical burns.

- – Industrial applications span multiple sectors, from lead-acid batteries to textile processing, making it an indispensable component of modern manufacturing.

Chemical Composition and Properties

Sulfuric acid, with its molecular formula H2SO4, stands as one of the most important compounds in industrial chemistry. This colorless, odorless liquid plays a crucial role in numerous chemical processes and applications.

Molecular Structure

The molecule consists of two hydrogen atoms, one sulfur atom, and four oxygen atoms arranged in a specific geometric pattern. The sulfur atom sits at the center, bonded to four oxygen atoms in a tetrahedral arrangement. Two of these oxygen atoms form hydroxyl groups (-OH) with hydrogen atoms, while the other two form double bonds with sulfur.

The compound exhibits strong acidic properties due to its ability to donate protons (H+ ions) in solution. When dissolved in water, sulfuric acid completely dissociates, releasing these protons in a two-step process.

Physical and Chemical Characteristics

At room temperature, pure sulfuric acid appears as a dense, viscous liquid with a specific gravity of 1.8302 g/cm³. It demonstrates remarkable hygroscopic properties, meaning it readily absorbs moisture from the air. This characteristic makes it an excellent dehydrating agent in various industrial processes.

The acid showcases exceptional thermal stability, with a boiling point of 337°C (639°F) and a melting point of 10°C (50°F). Its high boiling point results from strong intermolecular hydrogen bonding between molecules.

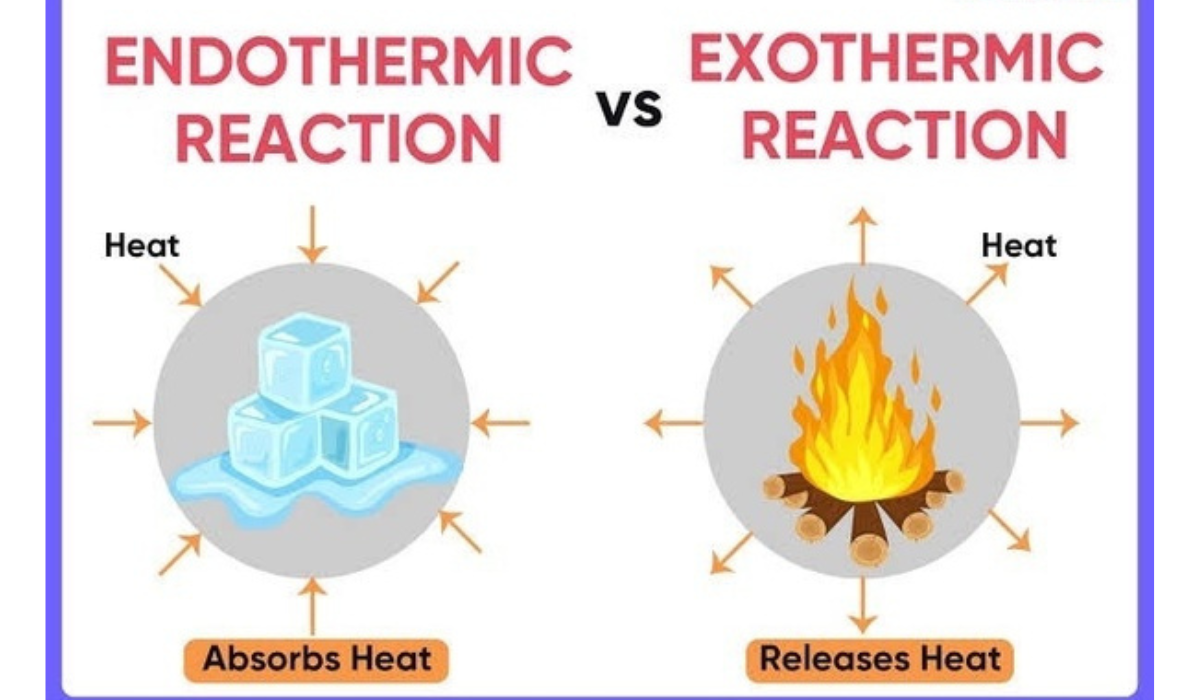

When mixed with water, sulfuric acid releases substantial heat through an exothermic reaction. This property requires careful handling, as the heat generated can cause dangerous splashing if water is added directly to concentrated acid.

The compound also exhibits strong oxidizing properties, capable of reacting with most metals to produce metal sulfates and hydrogen gas. Its corrosive nature makes it particularly effective in metal processing and cleaning applications.

💡 Key Takeaway: Sulfuric acid (H2SO4) is a dense, colorless liquid with strong acidic and oxidizing properties, characterized by its hygroscopic nature and high thermal stability, making it invaluable for industrial applications.

Industrial Manufacturing Methods

Sulfuric acid production has evolved significantly over the centuries, with modern manufacturing processes optimized for efficiency and safety. Today’s industrial-scale production primarily relies on two main methods that have revolutionized the chemical industry.

The Contact Process

The contact process stands as the most widely used method for manufacturing sulfuric acid on an industrial scale. This process begins with sulfur dioxide, which is typically obtained from burning sulfur or roasting metal sulfides. The sulfur dioxide then undergoes catalytic oxidation using vanadium pentoxide as a catalyst.

The reaction occurs at carefully controlled temperatures between 400-450°C to maintain optimal conversion rates. The resulting sulfur trioxide is then absorbed into concentrated sulfuric acid to form oleum, which is later diluted to produce the desired concentration of sulfuric acid.

The key steps in the contact process include:

– Sulfur burning to produce sulfur dioxide

– Purification of the sulfur dioxide gas

– Catalytic conversion to sulfur trioxide

– Absorption in concentrated sulfuric acid

– Dilution to desired concentration

Wet Sulfuric Acid Process

The wet sulfuric acid process offers an alternative manufacturing method, particularly valuable for processing hydrogen sulfide gas from petroleum refineries. This method helps reduce environmental impact by converting harmful waste gases into useful products.

In this process, hydrogen sulfide is first oxidized to sulfur dioxide in a furnace. The gas stream then passes through a converter where it transforms into sulfur trioxide using a catalyst. Finally, the sulfur trioxide combines with water in an absorption tower to form sulfuric acid.

The advantages of this process include:

– Lower environmental impact

– Efficient waste gas utilization

– Reduced energy consumption

– Higher production efficiency

– Better quality control

Both manufacturing methods incorporate sophisticated control systems and safety measures to ensure consistent product quality and worker protection. Modern plants often integrate heat recovery systems to improve energy efficiency and reduce operational costs.

💡 Key Takeaway: Modern sulfuric acid production primarily uses the contact process and wet sulfuric acid process, with advanced control systems ensuring efficient, safe manufacturing while minimizing environmental impact.

Industrial Applications

Sulfuric acid stands as a cornerstone in modern industrial processes, playing a vital role across numerous sectors. Its versatility and unique chemical properties make it an indispensable compound in manufacturing and production.

Manufacturing and Chemical Production

Sulfuric acid serves as a crucial component in various manufacturing processes. In fertilizer production, it reacts with phosphate rock to create phosphoric acid, which is essential for making phosphate fertilizers. The chemical industry relies heavily on sulfuric acid for producing detergents, synthetic fibers, and pharmaceuticals.

The petroleum industry utilizes sulfuric acid as a catalyst in alkylation processes, helping create high-octane gasoline. It’s also fundamental in metal processing, where it’s used for pickling steel and extracting copper, uranium, and other metals from their ores.

Industrial Processing and Applications

In the textile industry, sulfuric acid helps process fabrics and create synthetic fibers like rayon. The paper and pulp industry employs it for wood processing and pH adjustment. Battery manufacturers use a diluted form of sulfuric acid as an electrolyte in lead-acid batteries, commonly found in vehicles.

Water treatment facilities utilize sulfuric acid for pH control and water purification. In the food industry, it aids in the production of citric acid and corn syrup. The compound also plays a crucial role in wastewater treatment, helping neutralize alkaline effluents.

The electronics industry depends on sulfuric acid for cleaning and etching silicon wafers during semiconductor manufacturing. Its strong dehydrating properties make it valuable in drying gases and removing water from various industrial products.

💡 Key Takeaway: Sulfuric acid is a fundamental chemical in modern industry, essential for manufacturing fertilizers, processing metals, refining petroleum, and producing various consumer goods, making it one of the most important industrial chemicals worldwide.

Reactions and Chemical Behavior

Sulfuric acid stands out as one of the most reactive chemical compounds, known for its powerful interactions with various substances. Its behavior in chemical reactions makes it invaluable in numerous industrial processes and laboratory applications.

Strong Acidic Properties

Sulfuric acid exhibits exceptional acidic properties due to its ability to donate two protons in aqueous solutions. When dissolved in water, it undergoes a two-step dissociation process:

– First step: H2SO4 → H+ + HSO4- (complete dissociation)

– Second step: HSO4- → H+ + SO42- (partial dissociation)

This strong acid readily reacts with metals, producing metal sulfates and hydrogen gas. For example, when zinc reacts with sulfuric acid:

Zn + H2SO4 → ZnSO4 + H2

Dehydrating Properties

As a powerful dehydrating agent, sulfuric acid demonstrates remarkable ability to remove water molecules from various compounds:

– Converts carbohydrates to carbon by removing water molecules

– Dehydrates metal salts to form anhydrous compounds

– Extracts water from organic compounds, leading to charring

The acid’s hygroscopic nature means it actively absorbs moisture from the air, making it essential for drying gases and other chemical compounds in industrial processes. When concentrated sulfuric acid contacts water, it releases significant heat through an exothermic reaction, which requires careful handling during dilution.

💡 Key Takeaway: Sulfuric acid’s dual nature as a strong acid and powerful dehydrating agent, combined with its ability to participate in various chemical reactions, makes it an indispensable compound in chemical processes and industrial applications.

Environmental Impact and Natural Occurrence

Sulfuric acid plays a significant role in both natural processes and environmental concerns. Understanding its presence in nature and impact on our environment is crucial for maintaining ecological balance.

Natural Sources

Sulfuric acid occurs naturally through volcanic activity, where sulfur dioxide emissions react with atmospheric water vapor. Hot springs and geothermal vents also produce this compound through natural chemical processes. Certain bacteria, like Acidithiobacillus thiooxidans, can generate sulfuric acid by oxidizing sulfur compounds in soil.

The presence of sulfuric acid in nature serves as a vital component in the sulfur cycle, contributing to mineral weathering and soil formation. Volcanic lakes often contain high concentrations of this acid, creating unique ecosystems adapted to extreme acidity.

Environmental Effects

When released into the environment, sulfuric acid can have significant impacts. It’s a major contributor to acid rain formation when sulfur dioxide from industrial emissions combines with atmospheric moisture. This acidification affects:

– Soil chemistry and nutrient availability

– Aquatic ecosystems and marine life

– Plant growth and forest health

– Building materials and infrastructure

– Groundwater quality

Natural buffering systems in soil and water bodies help neutralize some acid deposition, but excessive amounts can overwhelm these mechanisms. Modern environmental regulations have helped reduce sulfuric acid emissions, leading to decreased acid rain incidents in many regions.

💡 Key Takeaway: Sulfuric acid exists naturally in volcanic regions and plays a crucial role in environmental processes, but its industrial release can lead to harmful effects like acid rain, impacting ecosystems and infrastructure.

Safety and Handling

Sulfuric acid demands careful handling due to its highly corrosive and reactive nature. Understanding proper safety protocols is crucial for anyone working with this powerful chemical compound.

Personal Protective Equipment (PPE)

When handling sulfuric acid, wearing appropriate PPE is non-negotiable. This includes chemical-resistant gloves, safety goggles, face shields, and acid-resistant clothing. A properly fitted respirator may be necessary when working with concentrated solutions or in areas with poor ventilation.

Always ensure access to emergency eyewash stations and safety showers in areas where sulfuric acid is used or stored. These facilities should be tested regularly to maintain proper functionality.

Storage and Emergency Procedures

Store sulfuric acid in well-ventilated areas away from incompatible materials like metals, organic compounds, and water. Use appropriate containers made of acid-resistant materials like glass or specific plastics. Keep containers tightly sealed and clearly labeled.

In case of spills, follow these essential steps:

– Evacuate the area immediately

– Alert emergency response personnel

– Use appropriate spill kits containing neutralizing agents

– Never attempt to dilute large spills with water

– Document all incidents and maintain detailed safety records

When diluting sulfuric acid, always remember to add acid to water slowly while stirring – never add water to acid. This prevents dangerous splashing and excessive heat generation that could lead to injury.

First aid measures should be readily available, including:

– Clean water for flushing exposed areas

– Neutralizing solutions

– Emergency contact numbers

– Clear evacuation routes

– Written emergency procedures

💡 Key Takeaway: Safe handling of sulfuric acid requires proper PPE, careful storage practices, and well-established emergency procedures to prevent accidents and respond effectively to potential hazards.

Comparative Analysis with Other Acids

Strength and Reactivity

Sulfuric acid stands out among common acids due to its exceptional strength and reactivity. When compared to hydrochloric acid (HCl) and nitric acid (HNO3), sulfuric acid demonstrates superior dehydrating properties and higher oxidizing power. Its diprotic nature means it can donate two protons per molecule, making it more potent than monoprotic acids.

Unlike hydrochloric acid, sulfuric acid can act as both an acid and an oxidizing agent. This dual functionality sets it apart in industrial applications where multiple chemical processes are required. The acid’s concentrated form (98%) exhibits remarkable reactivity with organic compounds, often leading to charring – a property not commonly seen in other mineral acids.

Industrial Applications Comparison

In terms of industrial usage, sulfuric acid outperforms other acids significantly. While hydrochloric acid is primarily used in metal cleaning and chloride production, sulfuric acid’s applications span across multiple industries. Its superior performance in fertilizer production, petroleum refining, and metal processing makes it the most widely produced industrial chemical.

Phosphoric acid, another important industrial acid, requires sulfuric acid for its production, highlighting the latter’s fundamental role in chemical manufacturing. Unlike nitric acid, which is mainly used in explosives and fertilizer production, sulfuric acid’s versatility extends to battery manufacturing, wastewater treatment, and ore processing.

💡 Key Takeaway: Sulfuric acid distinguishes itself from other acids through its superior strength, dual functionality as an acid and oxidizing agent, and unmatched versatility in industrial applications, making it the most important industrial chemical worldwide.

Conclusion

Sulfuric acid stands as a cornerstone of modern industrial chemistry, demonstrating its irreplaceable value through its diverse applications and unique properties. From its role as a powerful oxidizing agent to its crucial function in chemical synthesis, this compound continues to shape various industries and technological advancements. Understanding sulfuric acid’s properties, safety protocols, and industrial applications is essential for anyone involved in chemistry or manufacturing processes. Whether you’re working with the pure anhydrous form or dilute solutions, proper knowledge and handling procedures ensure both safety and optimal results. The compound’s significance in acid storage batteries, fertilizer production, and as a constituent of industrial processes underscores its continued importance in our technological world. As we advance into the future, sulfuric acid’s role in chemical synthesis and industrial applications will likely expand further, making it crucial to stay informed about this versatile compound. Remember to always prioritize safety and follow proper handling guidelines when working with this powerful mineral acid.

FAQs

What makes sulfuric acid the most widely used industrial chemical in the world?

Sulfuric acid’s versatility and reactivity make it indispensable in various industries. It’s crucial in manufacturing fertilizers, processing metals, producing chemicals, and creating batteries. Its strong acidic nature, dehydrating properties, and ability to act as an oxidizing agent contribute to its widespread industrial applications.

How does sulfuric acid contribute to acid rain formation?

Sulfuric acid is a major constituent of acid rain, forming when sulfur dioxide emissions from industrial processes react with atmospheric water and oxygen. This creates sulfuric acid aerosols that fall as precipitation, causing environmental damage to vegetation, aquatic ecosystems, and infrastructure.

Can sulfuric acid be stored safely at home?

Storing sulfuric acid at home is not recommended due to its highly corrosive and dangerous nature. It requires specialized acid storage containers, proper ventilation, and specific safety protocols. Only licensed facilities with proper safety measures should handle and store this powerful chemical.

How does sulfuric acid compare to other strong acids?

While sulfuric acid is one of the strongest common acids, it’s not the strongest overall. Fluoroantimonic acid and carborane superacids are stronger. However, sulfuric acid’s combination of strength, stability, and versatility makes it more practical for industrial applications.

What historical significance does sulfuric acid have in chemical development?

Sulfuric acid, historically known as oil of vitriol, was one of the first chemicals mass-produced through the lead chamber process. Its discovery by Abu Bakr Al-Razi and subsequent industrial production methods revolutionized chemical manufacturing and played a crucial role in the Industrial Revolution.

How does temperature affect sulfuric acid’s properties?

Temperature significantly influences sulfuric acid’s behavior. At higher temperatures, it becomes more reactive and corrosive. Its specific gravity and dielectric constant change with temperature variations, affecting its industrial applications and chemical reactions. Maintaining constant temperature is crucial for safe handling.

Post Comment